The medieval iron industry

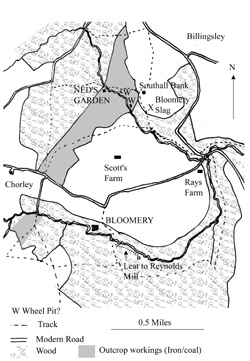

(This map shows the two bloomeries in Chorley.)

Shropshire is of course famous for its role in the history of iron making. Most people will be familiar with the story of Abraham Darby I, who pioneered the use of coal rather than charcoal to make molten iron in a blast furnace and so laid one of the foundations of the industrial revolution. Darby’s work took place in Coalbrookdale, in 1709. What is less well known is the very considerable prehistory of iron manufacture, much of which was centred around Chorley and Cleobury. Here I want to concentrate on the first part of the story, on how iron was made in the middle ages.

The raw material for iron is ironstone. This is typically found as orange nodules, mixed up with coal. Around Chorley, Billingsley and Baveney Wood, the ironstone is found close to the surface, close to where coal outcrops. Of course, there are also good outcrops on the Clee Hills. The outcrops are particularly easy to spot in streams, where the water has washed away the soil to expose a brown streak in the ground. Early prospectors would have noted these.

The second raw material for iron manufacture is carbon. The purest and most readily available source of carbon is charcoal made from wood. There are plenty of woods close to where the ironstone outcrops and it would have been a simple matter to convert the trees into charcoal. Thus the two main requirements for iron manufacture are close at hand.

In the very earliest ironworks, charcoal and iron ore are heated together. To get a sufficiently high temperature, bellows must be used to force a current of air through the fire. Eventually the ironstone reacts with the white-hot charcoal to leave metallic iron. The impurities form a slag. The temperatures that were reached in these early ironworks were not enough to melt the iron. Instead it would form a spongy mass called a bloom. This would be removed from the fire. It would then be beaten into a bar by a hammer; this also forced more slag out, giving a purer form of iron. The works where these operations were carried out was called a bloomery. In the early bloomeries, all operations were carried out by hand. However, later both the bellows and the hammers were powered by water wheels.

There are no good documentary records of any bloomeries at work in the locality. However, at two sites in Chorley there are large quantities of very distinctive slag that could only have come from a bloomery. One of these sites is in an area once known as Ned’s Garden, between Billingsley and Chorley and the other is between Rays Farm and Chorley. Both sites are on streams and in both cases there are traces of dams and water courses; it seems that both were water-powered bloomeries. The Ned’s Garden site is surrounded by numerous ironstone pits that must have supplied it with ore; the same mines also probably fed the other bloomery. Both are located on what were once roads.

Until recently, the date of both of these sites was unknown. Conventional wisdom has it that water power was not introduced to bloomeries until the 1400’s. However, pottery has now been found at the two sites. The bloomery by Rays Farm has given material from the 14th century; that at Ned’s Garden is 13th-14th century in date. Thus both are very early for water powered sites and may be pioneers.

Devotees of Time Team may recall Mick and Carenza getting very excited about a water- powered bloomery of this age they uncovered in Staffordshire last year which they claimed was of “national importance”. Chorley may have beaten Staffordshire to this technology!

The coming of the blast furnaces

(A cut-away sketch of a water-blown blast furnace)

(A cut-away sketch of a water-blown blast furnace)

In the previous article, I wrote about medieval iron making in this part of Shropshire. I argued that the iron works (bloomeries) around Billingsley and Chorley were technically sophisticated enterprises that would stand comparison with anywhere else in the region. None the less, they were limited in the amount of iron they could produce. Iron was used sparingly in medieval times.

Most people, when asked about the industrial revolution, will probably think of Abraham Darby, the furnace at Coalbrookdale and the “cradle of the industrial revolution”. The latter phrase has been remarkedly successful; I have been told it was invented by the Telford Development Corporation after “Telford; the home of industry” started to become something of an embarrassment. However, whilst it is a great slogan, it is also untrue.

As far as iron working is concerned, the real technical revolution occurred not in Coalbrookdale in 1709, but somewhere in Europe around the 15th century. In the old bloomery process for making iron, the iron itself was never produced as a liquid. However, it was discovered that if a strong current of air was applied to the furnace, the iron would melt. This could be cast directly into moulds. The resulting cast iron was very brittle and had only a few uses; however if it was reheated in a forge, it was turned into wrought iron that was equal to anything that could be made in a bloomery. The real advantage was the amount of iron that could be made. In the course of a year a bloomery’s output would be a few tens of tons; by contrast even a small blast furnace would produce ten times this. Suddenly the way was open to cheap, mass-produced iron.

The first blast furnace appeared in Britain in the Weald, on the south coast, in 1496. For the next century or so, this was the centre of iron making, close to London and with plenty of good quality iron ore. However, as the 16th century progressed, the new technology started to spread. About 1561, a blast furnace was built on Cannock Chase. By 1570 there were about another half dozen, including one (possibly two) in Shropshire. By 1576, these pioneers had been joined by two in the Wyre Forest, on the boundaries of Kinlet and Cleobury Mortimer.

Cleobury and much of the forest had been acquired by Robert Dudley in 1563, advisor to and lover of Queen Elizabeth I. Next year, Elizabeth made him Earl of Leicester. Dudley had family connections with the iron masters of the Weald and so knew of the potential of the iron trade. The new technology needed a strong stream to power bellows for the furnaces, a good source of iron ore and plenty of wood to make charcoal. The Wyre Forest provided charcoal, iron ore was found on the Clee Hills and Neen Savage as well as Billingsley and Chorley and the Dowles Brook provided water power. By 1576 Dudley had built two furnaces. One was at the present Furnace Mill, on the Kinlet Cleobury boundary and the other was about ½ a mile further upstream, on the Kinlet bank of the brook. Both were leased to a tenant called John Weston, who lived in Neen Savage. The cast iron produced by these furnaces would only have had limited uses and so one or more forges also needed to be built to turn it into wrought iron. These were put up on the Rea, close to Cleobury Mortimer; almost certainly the later Upper and Lower Forges. It seems that Dudley invested wisely; in the 1580s he apparently made around £1600 pa from his ironworks.

Whilst the furnaces were profitable in the 16th century, there is no documentary evidence that they were still at work after 1600. However the forges were still busy, so iron making must have been carried out somewhere in the locality. Certainly by 1630 a furnace was operating at Catherton, on the edge of the common and later in the century another was at work just below Ditton Mill, on the lower slopes of the Clee. By 1641 Furnace Mill was just that; a corn mill and its neighbour further upstream appears to have been completely abandoned. None the less, even today Dowles Brook is full of glassy-green slag, the products of these two pioneers of the real revolution in iron production.

The John Weston of Neen Savage

The introduction of blast furnaces to the area owed much to the energetic 16th century entrepreneur , John Weston.

We know next to nothing about where John Weston came from. Instead, he suddenly bursts into the local records in 1576 when he took the lease on a pair of blast furnaces in the Wyre Forest. These were on the Dowles Brook. One was at Furnace Mill on the narrow road that leads from Kinlet to Far Forest and the other was about a mile upstream, at a site that is now completely abandoned. Although blast furnaces as a way of making iron had been at work in south-east England for over ¾ of a century in 1576, very few had been built outside this area and so Weston was very much of a pioneer. He appears to have settled down at Cleobury Lodge Farm (actually in Neen Savage) where he lived with Alice his wife, Margery Strong his mother-in-law, and his children of whom we know there were at least two. To be able to afford to lease the furnaces means that he must have been fairly well off; however, he was clearly not amongst the elite of the gentry.

Weston’s career as a pioneer iron master is interesting enough, but by itself it would not have marked him out as anything particularly special. What makes him of more than passing interest is his involvement in copper mining and smelting in Cornwall and South Wales at the same time as he was operating his furnaces in the Wyre Forest. Until the reign of Queen Elizabeth, little or no copper was produced or smelted in this country. However, a group of German miners were enticed to this country and given a monopoly to produce copper, under the title of the Company of the Mines Royal. They concentrated their efforts in the Lake District, ultimately to little avail. In 1582, Weston and a partner leased all the copper mines in Cornwall from them. We have no good information as to how Weston came to be involved in copper mining. One clue might be that he leased his blast furnace from Robert Dudley, Earl of Essex and Dudley was also a partner in the Mines Royal. Perhaps it was through Dudley that he became involved in copper mining.

Weston’s exact role in the Cornish copper mines has been the subject of much argument. He is perhaps best viewed as a middle man; he had other, probably wealthier partners, but he appears to have been the driving force and the man concerned with day-to-day management of the concern. He did have a professional mine manager to advise him; a notably melancholic German called Ulrich Fosse. Fosse had little time for Weston, dismissing him as a “young scholar” and blaming him for all the misfortunes at the mine. Weston appeared to have had equally little time for Fosse, eventually shunting him off to Neath in South Wales, where the Cornish copper was being smelted with Welsh coal and charcoal. However, Weston was also a frequent visitor here and claimed to have invented a new method for producing copper.

Weston left a trail of correspondence as he shuttled between Neen Savage, Cornwall, Neath and London in the early 1580’s, much of it from his frustrated business partners or the ever more grumpy Fosse. Suddenly it all comes to an end. The explanation is in the Neen Savage parish registers: Weston died suddenly in July 1584.

We simply cannot judge whether Weston was a genuine industrial pioneer or merely a middle-man on the make; his sudden death brought a swift end to his works in Cornwall, although Alice operated the blast furnaces until the end of their lease. It would have been fascinating to watch his career develop.

Local forges

From the late 16th century onwards, local iron was produced in blast furnaces. The product of this was cast iron. As it was produced as a liquid from the furnace, it could be poured into moulds and so could be directly formed into many different objects. However, it has a very serious problem: it is very brittle. For some castings this does not matter, but for anything that is subject to being knocked or bumped in the course of use, this is a fatal weakness. Fortunately the iron can be made much more malleable by a process of reheating. This produces wrought iron and until the introduction of large-scale steel manufacture in the 19th century, it was by far the most important material derived from iron. The process of making wrought iron was carried out in forges and many existed on streams in this area.

The earliest and longest lived forges were at Cleobury. These must have been built at the same time as the first blast furnaces, around 1570. Their sites are still known as upper and lower forges, on the River Rea. Essentially the “pig iron”, the cast iron from the furnace, was remelted and subject to a process of hammering. Thus water wheels were needed to operate both bellows and the large forge hammer. The forges at Cleobury had a complicated history. They long outlived the original furnaces in the Wyre Forest, instead buying their iron from other furnaces in the general locality. In the later part of the 18th century they specialised in tinplate manufacture, under the direction of an Irish-born, Birmingham-established entrepreneur called John Florey. The forges finally closed around 1815.

On the Rea in Stottesdon there were three forges; Prescott Forge, Hardwick Forge and Rotherham Forge. Prescott Forge was on the site of the present Prescott Mill. In 1708, Peter Hussey, a frying pan maker from Wolverley, was granted a lease to take over an existing corn mill and turn it into a forge. In the 1730’s he established a second forge at Hardwick, about half a mile upstream of Prescott. It may be that he continued his trade of pan making, using a water-powered hammer to draw out the thin plates needed for these utensils. By the middle of the century, Prescott seems to have closed and Hardwick was now leased by Cornelius Hallen. Hallen came from a long line of iron-workers based originally in East Shropshire; like Hussey, he seems to have continued making frying pans and similar objects: shovels, boiler plates and so forth. Cornelius’s son, Samuel, made his home at Hardwick and what is presumably his house still survives. His tombstone, recording his death and the subsequent deaths of many of his family, is next the chancel in Stottesdon graveyard.

In 1759, Sam Hallen went into partnership with Robert Palmer of Coalbrookdale, a timber merchant, to build a brand new forge about half a mile downstream of the old Prescott Forge. This new forge was also, confusingly, called Prescott Forge for a period, but soon was known as Rotherham Forge. I have no idea why! I suspect that, unlike Hardwick, Rotherham did not specialise in iron plate production but perhaps made other types of iron such as bar iron. It seems to have done well at first, but must have suffered as the iron industry became more concentrated in East Shropshire and the Black Country. The forge was sold in 1791 to John Glover, who already owned most of Farlow and Cleeton. Samuel and his brother John went bankrupt in 1794 and Glover turned the forge, improbably, into a cotton mill.

Hampton Loade Blast Furnace

For many years, one of the more puzzling questions about Highley concerned one John Legas, who lived somewhere in the north of the village in the middle of the seventeenth century. The mystery concerned his trade; John was a pot founder. As the name suggests, a pot founder was a metal worker; a man who made cast iron pots, for cooking or boiling things in. Both myself and Gwyneth Nair, (the local historian who first told me about John) knew that at this time Highley was largely an agricultural village. What was John doing living here?

This question was answered by another historian who I was talking to, some years later. Peter King specialises in the history of the iron industry; he told me that he had uncovered several references to a blast furnace at Hampton Loade at this period. A blast furnace is where iron ore is turned into iron, which can then be used for casting. This is exactly the type of place that would have required a pot founder such as John Legas. Peter was able to provide me with references from which I was able to learn more about this forgotten furnace.

The furnace seems to have been built in about 1640 by Thomas Foley on the banks of Paper Mill brook; the boundary between Quatt and Alveley and the site of the present Hampton Loade ferry. Thomas Foley was probably the most important iron master of his day in the West Midlands; he and his relatives controlled a network of furnaces and forges from the Forest of Dean to Cheshire. At its heart lay a series of works on the River Stour. These took iron ore, first of all turning it into cast iron and then refining some of it to make wrought iron; the raw material for blacksmiths, nail makers and all manner of allied trades. The forge at Hampton took a supply of water from the brook which was used to drive a water wheel, which in turn drove the bellows needed for the furnace. The first mention of the furnace is in 1641 when Foley agreed to compensate a miller at Alveley for any problems the furnace water supply might cause to his mill.

At this date, furnaces used charcoal rather than coke for fuel. Hampton probably drew its charcoal both from the Wyre Forest and the woods along the Severn and Borle valleys. There are also references to wood coming probably from Dudmaston. There is no clue as to where the iron ore came from, but the nearest source would be Billinglsey and Chorley. The records include payment to John Legas in 1662 for making pots at Hampton.

The 1662 reference is the last mention of Hampton and it probably closed not long afterwards. Peter King suspects that its lease was up and Thomas did not think it worth renewing; he had other furnaces nearer his Stour valley mills.

There are no obvious remains of the furnace today. I have found a piece of blast furnace slag on the river bank at Hampton that must have come from the furnace. Almost certainly the furnace stood on the site that was later turned into the forge in 1796; I suspect that the forge reused the old furnace water course and pool for its own purposes. It is possible that somewhere, buried beneath a later road and buildings, the foundations of the furnace still exist. A fuller account of the furnace appears in Transactions of the Alveley Historical Society.

More on iron working

In early 2006, the Four Parishes Heritage Group received a grant from the Local Heritage Initiative to investigate the local iron working industry. In the last few weeks we have made some major advances with our research.

In the brook valleys that border Chorley, Kinlet and Billingsley are the remains of two iron works. All that is now visible are large piles of slag. However, the slag was enough to show that the ironworks dated from the medieval period. They were examples of “bloomeries”, where iron was made before the introduction of blast furnaces in the 16th century. In these, the iron ore was heated so that the slag was turned to a liquid but the iron remained as a solid lump. The slag was run off and the iron was beaten with a hammer to form it into a bar that could be used by blacksmiths. The process could only make small amounts of iron, although the quality was usually very good.

We had several questions we were interested in. We wanted to know the dates of our bloomeries, how big they were and how exactly they worked. To do this, we employed a team of archaeologists. As both bloomeries are in Sites of Special Scientific Interest, we cannot carry out any excavations. However, our archeologists from GeoArch are specialists in geophysical surveys, which use sophisticated equipment to detect features that are buried under the ground. For two weeks in January, Tim Young and Andy, his assistant, braved gales and freezing temperatures to survey our sites.

Both sites seem very similar. Tim thinks they belong to the late medieval period; 14th-15th centuries. This fits with the very slender documentary evidence that we have and also the few scraps of pottery found on the sites. Tim previously helped “Timeteam” with a late medieval bloomery in Staffordshire and he sees similarities between that site and ours. The geophysics have shown that high above the stream there are a series of buried features. These probably represent furnaces where the ore was turned into iron or they would be “ore roasters”. Before being put in the furnace the ore was first heated in large heaps; this started the chemical reactions that would be needed to convert it into metallic iron. There are then large heaps of slag stretching down to the brooks. The geophysics show further possible structures close to the brooks and these may also be furnaces. During the 14th and 15th centuries, iron making was mechanised with water wheels being used to power bellows; it is possible that we have some of these water-powered furnaces. One of our sites, between Billingsley and Chorley, does have what seems to be a dam. However, the geophysics showed no sign of iron working by this and it may be either a natural feature or it could have been built in the 18th century as part of a scheme to drain the mines then at work in Billingsley. Both sites also have evidence for activity in the 17th or 18th centuries, with foundations of buildings. It is possible that these may have been originally built for the ironworkers and then converted to other uses once the works closed.

Both iron works must have been large affairs, considering the volume of slag they produced. Given their size and date, Tim thinks that they are very important survivors that could tell us a lot more about this early phase of iron making in Shropshire.

Bloomery Dam. This is the site of a bloomery close to Chorley village. There would have been a dam across the stream to create a head of water to drive a water wheel. This in turn would have operated bellows or a hammer at the bloomery.

Bloomery Dam. This is the site of a bloomery close to Chorley village. There would have been a dam across the stream to create a head of water to drive a water wheel. This in turn would have operated bellows or a hammer at the bloomery.

This work was carried out by the Four Parishes Heritage Group on a project supported by the Local Heritage Initiative and funded by the Heritage Lottery Fund and the Nationwide Building Society.

The bloomery breathes again

The Four Parishes Heritage Group’s main project, funded by the Local Heritage Initiative, has been to investigate the local iron industry, whose remains can be found deep in the stream valleys around Highley, Kinlet, Billingsley and Stottesdon. More specifically, we have been particularly interested in the medieval iron industry.

Today, iron is made in a blast furnace. With the help of a strong current of air (the “blast”), the temperature inside a furnace reaches well over 1600ºC. This causes the newly formed metallic iron to melt; it can be drained out of the furnace directly to moulds to form castings or simply allowed to form bars which are subsequently refined and used for other purposes. However, reaching such high temperatures is not easy; the first blast furnace was not introduced into this country until the very end of the 15th century. Prior to that, iron was made on a much smaller scale, in a structure known as a bloomery. Typically this would be a clay cylinder, around 3 feet high and about 1 foot in diameter. Although in late medieval times, a water wheel was usually adapted to drive a pair of bellows, in earlier times the bellows would simply be worked by hand. The temperature usually does not get above 1200º C. Whilst this is hot enough to cause the impurities in the iron to melt, forming a liquid slag, the metal itself stays as a solid. Thus the slag would be drained off, the lump of iron retrieved with a pair of tongs and then hammered on an anvil to form a consolidated lump of metal called a bloom. Whilst an early blast furnace would produce several hundred tons of iron a year, a bloomery would have had an output of about 30 tons pa. Thus the advantages of the new technology were obvious, although the quality of the iron from the bloomery was better than from a blast furnace.

Over the last few months, our bloomery sites have been investigated by Dr Tim Young, of GeoArch. Tim, an archaeologist who specialises in the history and archaeology of metal working, is one of the leading authorities on iron working. He is currently examining slag samples from our furnaces, to try and work out exactly how they operated. However, as part of our project, he is also going to attempt to rebuild a bloomery and use it to smelt local iron ore, so we can see how the process looked and also try and reproduce the type of iron that would have been made.

The reconstruction will take place on the Alveley site of the Severn Valley Country Park, next to the visitor centre. The furnace will be built on 26th/27th June (2007). For reasons of practicalities, we will cheat slightly and use modern firebricks to strengthen the structure, but the bulk will still be made from the traditional clay. We have been given a ton of fireclay by Caughley Quarry of Broseley. Currently this is in the form of a crumbly powder and our main task on the 26th will be to mix it with water to turn it back into a clay, which can be moulded to cover the bricks. The choice of clay is very important as it takes part in the chemical reactions which lead to the production of metallic iron; we also have a small sample of more local clay from Billingsley which we will use to line the inside of the furnace, to try and mimic what would have happened with our bloomeries. The charcoal is being produced by Kinlet charcoal burner Dave Allen, from local oak wood. The iron ore is also local—either from Chorley or from the pit mound at Alveley (geologically equivalent to the ore from Billingsley and Chorley).

We will allow a month for the furnace to dry out. Firing will take place over the weekend 21st/22nd July, beginning around 10.00 am each morning and supervised by Tim. All are welcome to come and look or even (with appropriate supervision), have a go at working the iron. It promises to be a dramatic event, with a great deal of flames, sparks and smoke. It will also be a unique insight into the world of the medieval ironmakers, the remains of whose efforts we have spent the last year trying to understand.

This work was carried out by the Four Parishes Heritage Group on a project supported by the Local Heritage Initiative and funded by the Heritage Lottery Fund and the Nationwide Building Society.

The bloomery breathed again

Two months ago, I reported how we hoped to build and fire a medieval iron furnace (a bloomery) at the Alveley site of the Severn Valley Country Park on the weekend 21st/22nd July. Those of you who can think back several weeks will recall that was the weekend of the floods (well, the July floods as opposed to the June floods). Virtually every event in the West Midlands was abandoned. Apart from one. I am delighted to report that we beat the weather.

We did have to make some concessions to adverse conditions. Whilst we had built the furnace a couple of days just after the June floods, it needed some preparation before it could be used. Dr Tim Young, our archaeologist from GeoArch and his colleague, blacksmith Aaron Peterson, set off from their homes in Cardiff on the Friday afternoon to do this, but at 10.30 pm on the motorway were forced to turn back, eventually arriving back home at 2.00 am on Saturday. Undaunted, after a few hours sleep they set out again and managed to get to the Country Park at about 3.00 pm. They checked the furnace and lit a small fire to dry it out and start the process of heating it up.

Fortunately Sunday stayed dry and Tim and Aaron started operations at 9.00 am. The furnace was relit and fed with alternate buckets of charcoal and iron ore. We had already prepared the ore by heating it in a bonfire a week before. This operation, known as ore roasting, starts the chemical changes that turns ore into iron metal. Charcoal was used rather than coal, as coal would introduce too many impurities into the iron. To make the furnace burn hotter, an electric blower was used, although this would do no more than provide the same force of air that would have been used at a late medieval furnace, such as operated in Chorley.

We had 200Kg of charcoal and it soon became apparent that we would use most of it as the furnace consumed it at a very fast rate. By 2.00 it was time to tap the furnace to see what had been produced. The essence of the bloomery is that the iron remains solid, as a spongy mass, whilst the impurities form a liquid slag that runs away. We found we had produced a large lump of iron and slag in the bottom of the furnace, about a cubic foot in size. With some difficulty this was lifted out of the furnace and some of the slag was knocked clear.

The second stage of the bloomery process was to produce a lump of iron from the spongy mass taken from the furnace. For this, the furnace was reduced in size by around a foot to give a smithing hearth. The lump was then put back on it with fresh charcoal and reheated. With successive hammerings, the iron should be consolidated into a solid lump, known as a bloom. This can be used straight away by a blacksmith. We had only partial success with this, as our iron lump had a very loose structure and it was not possible to properly consolidate it. However, we had clearly turned the ore into something metallic!

As well as providing a spectacle, we learnt a lot from the exercise. The reason we had only a little iron was because the furnace had consumed its charcoal too quickly; the charcoal is not just present to provide heat, it needs to react chemically with the ore. This means that the furnaces in Billingsley and Chorley were probably larger than the one we built; perhaps 5’ tall, to hold enough charcoal. This in turn would mean that they would have produced a lot of iron and explains why the slag mounds are so large.

Our medieval furnaces also produced a much more liquid slag than we got. Our furnace was lined with fireclay; the medieval ironmasters probably used a less heat-resistant clay that would react with the ore to produce a flux, to make the slag more liquid.

The day ended in bright sunshine; our only regret is that we had not brought any food to cook on the hot embers from the furnace!

This work was carried out by the Four Parishes Heritage Group on a project supported by the Local Heritage Initiative and funded by the Heritage Lottery Fund and the Nationwide Building Society.

Back to the bloomeries

In early 2006, the Four Parishes Heritage Group were awarded a little over £23,000 by the Local Heritage Initiative. The main purpose of this grant was to investigate the history and archaeology of a number of medieval ironworks in the woods between Chorley, Kinlet and Billingsley. Our initial aim was to carry out a geophysical survey of the ironworks, in the hope that this technology would give us some ideas of what was beneath the ground. This was certainly successful.

Dr Tim Young from GeoArch carried out the work for us. At the site between Billingsley and Chorley (Ned’s Garden), there was evidence for large dumps of slag and sites for roasting iron ore. This is an important step in which the iron ore is preheated before it is actually smelted to turn it into metallic iron. It was not clear if we had any remains of the iron smelting furnaces themselves, but we did find evidence of buildings that were probably contemporary with the furnaces. At the other site, Fiddle Bloomery, we found much the same as at Ned’s Garden, but there was also good evidence for the use of water power for bellows and here there was better evidence that a furnace might have survived. In addition, at both sites there was evidence for reuse after the medieval period.

Impressive though the results from the geophysics were, there is no substitute for actually digging to reveal exactly what survives below the ground. We were fortunate in that we found that we had sufficient money left over in the grant to be able to bring Tim back to do some excavation for us. At the time of writing, Tim and his team are just about to start work. Getting this far has not been easy as both our bloomeries are in Sites of Special Scientific Interest (SSSIs) and there have been extensive negotiations with Natural England to allow us to dig. We are also particularly grateful to the landowners who have been very supportive of our project.

The excavations will last a week. Essentially Tim will be carrying out an evaluation, digging a small number of trenches to see what exactly survives below ground. This will allow him to interpret the geophysics with more confidence. He will also be searching for dating evidence. There is much charcoal and pottery on the surface of both sites, but we have no idea of exactly where it comes from within the sites. It is important to recover undisturbed buried material; stratified deposits. These will allow us to date different layers that might exist within the sites and so help elucidate their histories. It is likely that the main datable material that we will find is charcoal, which can be radiocarbon dated.

Tn addition to digging, there is evidence on both sites for dams. We will cut sections through these to try and learn more about their histories. Tim suspects that water power was only used at Fiddle Bloomery; the dam at Ned’s Garden may relate to a later use of the site or it may even be a natural feature.

With the conclusion of the digs, our LHI-funded project will come to an end. However, there remains much to learn about both these sites and other related sites locally. In particular, within the Wyre Forest in Kinlet are two early blast furnaces which we are keen to explore. We hope we may be able to obtain more funds to extend our work.

The Four Parishes Heritage Group are supported by the Local Heritage Initiative and funded by the Heritage Lottery Fund and the Nationwide Building Society.

Ned’s garden uncovered

Last month (previous article on this page), I recapped how the Four Parishes Heritage Group had been awarded a grant by the Local Heritage Initiative to look at a pair of medieval ironworks (known as bloomeries) in the woods between Chorley, Kinlet and Billingsley. Dr Tim Young and his colleagues from GeoArch previously carried out a geophysical survey of the ironworks. This revealed tantalising evidence of buried structures at both sites and so we invited Tim back at the start of May to carry out excavation. The aim was to do small-scale evaluations at both of our sites: Ned’s Garden, between Chorley and Billingsley, and Fiddle Bloomery, close to Ray’s Farm. In the event, Tim and his colleagues uncovered so much at Ned’s Garden that we spent the entire time on that site, trying to understand it.

Previously, we knew that there had been medieval iron-smelting at Ned’s Garden. We were not sure of the date, but my suspicions were that the site was probably working some time around 1300-1500. There was some suggestion of a dam to power a water wheel but the evidence for this was unclear. We also knew that in the late 17th or early 18th centuries there had been some activity on the site, based on pottery and fragments of brick.

Tim’s first task was to put a trench down on where he thought there was a building, based on the geophysics and also the presence of a lot of stone rubble. After a couple of feet of digging, we exposed a stone wall and a floor made of flagstones; we had a building. We were fortunate enough to find not only the wall, but a doorway as well. There was a lot of pottery on the floor of the building, dating from when it was abandoned. We are currently having all the pottery from the excavation dated properly, but that from within the building (almost certainly a house) looked to be about 1650-1700.

Outside the building, there was a lot of slag from the ironworks. However, the pottery found mixed up in this was largely 17th or 18th century. It is inconceivable that the ironworks would have been in production as late as that; the bloomery process was obsolete in Shropshire by the end of the 16th century. However, bloomery slag is rich in iron and was quarried by 17th and 18th century ironmasters, to feed their blast furnaces. We suspect that the slag dumps were comprehensively reworked during this period, explaining the pottery. We also know that coal and ironstone were being mined in the woods adjacent, of which more anon. We did however find a little medieval pottery in the slag, probably from the 13th-14th centuries. One of our big surprises was when we lifted the floor of our house. Here at last we could get into an undisturbed slag dump; it was full of medieval pottery but much earlier than we were expecting. It looks as though the bloomery may have started life in late Norman times, in the 12th century.

We finally found conclusive proof of the use of water power, when a second trench came down on a water course, built to take water from the brook to a waterwheel. We have no direct date for this, but currently our best guess is that it is probably 17th or 18th century. We know that in the early 18th century, coal mines around here were drained by a pump worked from a water wheel; we suspect that we have found the channel for this wheel.

This was a very productive dig and a spectacular end to our LHI project! However, the group continues so look out for more on the history of our sites.

The Four Parishes Heritage Group are supported by the Local Heritage Initiative and funded by the Heritage Lottery Fund and the Nationwide Building Society.

Fiddle bloomery uncovered

The Four Parishes Heritage Group have spent much of the last two years looking at a pair of medieval ironworks (known as bloomeries) in the woods between Chorley, Kinlet and Billingsley. Dr Tim Young and his colleagues from GeoArch previously carried out a geophysical survey of the ironworks and in May he carried out trial excavations at the one site, Ned’s Garden, between Billingsley and Chorley. This showed us that it dated from the 13th century. In October (2008) Tim and his colleagues, Kate and Andy, came back to repeat the exercise at the second of our sites, Fiddle Bloomery, between Chorley and Rays Farm.

We suspected that Fiddle Bloomery might have been later than Ned’s Garden as there was clear evidence that it had once been operated by a water wheel. Indeed, the former water channel still holds water today after heavy rain. We also know that after the site stopped working a house was built for a miller, who operated a corn mill called Reynold’s Mill somewhere in the vicinity. To investigate the site, Tim, Kate and Andy dug a single trench across the water course, into a slag dump on the one side and into what we hoped would be the working floor of the ironworks on the other side. They very quickly confirmed that there was a working floor, with much debris from slag, ironstone and charcoal. However, this did not give any pottery that could be dated properly. The slag dump also proved to be devoid of any dateable material. We always suspected that the most likely place where we would find broken pottery would be at the base of the water course, where such items would naturally be thrown. So our intrepid archaeologists spent the next five days digging 6 feet down through wet slag in an attempt to get to the bottom of the channel. The upper layers provided a lot of pottery, but this was all 17th-18th century, from the later house. It soon became apparent that when the ironworks stopped operating, the channel had been deliberately filled with slag; this was probably the only way to stop the brook from constantly refilling it. It did however make for particularly hard digging. We had not anticipated that the channel would be so deep; when, on Sunday, we hit the water table with still no sight of the bottom, we did wonder if the dig would end up like one of Time Team’s less memorable episodes.

Fortunately relief came on Monday, when, helped by some bailing with a bucket, the edges of the channel finally emerged. We never did find the bottom, but in the silt around the one edge, some undisturbed pottery was found. This is mid to late 15th century and means that our ironworks were established around 1450-1500. There is no evidence that the water course was in use before then and so we think that it was built on a new site. Neither is there any evidence for reuse of the channel afterwards; hence we think that Reynold’s Mill, probably the same as Chorley Mill known from documents of c1300, was a little further downstream. We do not know how long the works operated, but I suspect it probably stopped working early in the 16th century.

We did not find the furnace itself, but the trench was deliberately placed to minimise this; we did not have the resources to excavate the structure properly. However, based on the earlier geophysics results, we have a very good idea of where it might be and the current excavation suggests that it is likely to be largely undisturbed. We know very little about how water power was applied to iron works in late medieval times, but this was a vital stepping stone to the development of the blast furnace, which revolutionised iron production in the 16th century. At Fiddle, we are in a good place to fill this gap; it is an archaeological site that is of national importance.

Highley bricks

Brick making is not a glamorous industry; it does not have eye-catching monuments such as the headframes of coal mines nor does it leave dramatic scars on the landscape like quarries. However, its products are part of our everyday lives and the local countryside has been peppered with brick pits and kilns. It is as much a local industry as is coal mining; indeed the two have often been connected.

In Highley, the earliest building that looks to have been built from bricks is the south part of Netherton House, perhaps dating from the late 17th century. Bricks had been used locally for 200 years previous to this, but they only started to become common towards 1700. The earliest known brickmaker who worked in Highley was Robert Evans, operating in the early 18th Century. He built a row of cottages at Cherry Orchard. In the fields around Netherton there are a few ponds with suspiciously straight sides; these may be pits where Robert or his contemporaries dug clay. There are farms where bricks with dates from the 18th Century can be found; these would have been made close to where they were used and fired in temporary kilns.

Commercial brick making came to Highley in the late 19th century and its history is intertwined with that of the Highley Mining Company. Before the main colliery was sunk in 1878/9, the company opened a brickyard, just below what is now the Pen Factory. They sank a pair of shallow shafts to get coal to use at their brickyard. The probability is that the brick works was simply a short term measure to provide income for the company before they completed their mine at Highley. The brickyard was in existence by 1877; there is an ambiguous reference to a brickyard at Highley in 1875 but the description of it suggests that it might have been the brickyard at Billingsley.

The records of the Highley Mining Company in its earliest years show money being spent at the brick works on new kilns and also brick-making machinery. However, some bricks were also made by hand. The works were sublet to contractors who agreed a price with the company to make the bricks; these men were usually from Staffordshire, like most of the people associated with the company at this time. The yard was worked on and off as required; it provided bricks for the colliery but its first big order was probably for the building of Silverdale Terrace.

The layout of the brickyard can be seen on Ordnance Survey maps of 1881 and 1902. The earlier map shows an irregular-shaped building that probably held the clay preparation and brick-making machinery; the clay was ground in a mill before being squeezed through a die and cut by wire into bricks. A long rectangular building must have been the drying shed, where the newly made bricks were allowed to dry in the air for a few weeks. Finally, there were three beehive kilns, where the bricks were fired. In 1902 the brick-making shed was smaller, but was now served by a rail track that fed it with clay from the quarry. Two of the beehive kilns had been demolished but the drying shed was twice the size; it might have been extended to include a new kiln. At this time the yard was likely to have been very busy, as Barke Street, Orchard Street and Coronation Street were being built; probably several hundred thousand bricks were produced each year. Output then dwindled to just a few thousand, but picked up again in 1912. Clee View was built this year, although most of the bricks for that came from Billingsley; it is more likely that the yard was supplying bricks for building in the village. However, after 1916 Billingsley brickyard seems to have stopped working and all local bricks would have come from Highley.

The brickyard remained active until at least 1927; in 1926 the output was over 90,000 bricks, although this was a particular high. However, it seems likely that it closed shortly after that. There was little building in Highley and larger brick-yards with better transport links could supply the locality. The buildings remained up for many years; the drying sheds were used to store cores from boreholes sunk by the Highley Mining Company and the tubs that ran on the narrow gauge railway within the brick quarry were a source of fascination to the small boys of the village who attempted to turn them into racing carts.

John Hazledine

In July (2009), Bridgnorth will again host a steam engine rally on the Severn Park, to mark the connection between the town and the early steam locomotive “Catch me who can”; the first in the world to carry fare-paying passengers. It is well-known that this locomotive was built at Bridgnorth Iron Foundry, close to the present Severn Park, for Richard Trevithick, the famous Cornish engineer. At Bridgnorth, the role of the foundry engineer, John Rastrick, has been celebrated; Rastrick himself became a pioneer of railways, designing locomotives and building railway lines. However, the foundry itself was owned by John Hazledine, a man who has often been overlooked. Yet Hazledine himself was a very capable engineer who has connections with Highley, Hampton Loade, as well as Bridgnorth.

John Hazledine was born in 1760, the son of a millwright, William. He was the eldest of four children. He was apprenticed to his uncle in 1774 and it was from him that he probably learnt the rudiments of engineering. In 1782 he married one Ann Davies of Eardington and it is possible that he was employed at Eardington Forge, which opened in about 1777. At forges such as Eardington, pig iron, the product of blast furnaces, was processed to turn it into wrought iron, for use by blacksmiths. The pig iron could also be sold to foundries, where it was remelted and used for castings.

Although John was probably gaining experience of the iron trade after his marriage, the first reference to him in Bridgnorth, in 1791 when he purchased a tenement in Low Town, described him as a maltster, i.e., a person who supplied malt to brewers. However, by 1794, my colleague Dr Peter King has shown that he was in partnership with one Hallen in Bridgnorth and was purchasing pig iron; he had now established his foundry at Bridgnorth. “Hallen” was probably William Hallen of Upton Forge; by 1797 this William with his partner at Upton, John Wheeler, was in business with Hazledine. As John Wheeler had previously been at Eardington, it is easy to see how a connection with Hazledine might have been established.

John Hazledine appears to have remained the senior partner at Bridgnorth Foundry for the rest of his life, during which time it established a national reputation for the quality of its castings. However, Hazledine does not seem to have benefited much from the success of the foundry. In 1797 he was declared bankrupt. He was involved in a web of business dealings; with John Wheeler and William Hallen in the iron trade, William Hallen and George Hallen in a spinning mill at Eardington and also with Robert Thompson, a tanner of Bridgnorth. Hazledine, the Hallens and Wheeler, all went bankrupt at the same time, suggesting some kind of collective failure.

Hazledine seems to have come to some accommodation with his creditors fairly rapidly and was able to continue at the foundry, although his insolvency would later come back to haunt him. The year after his bankruptcy, Hazledine took out a patent on an improved mill for rolling iron and other metals into bars; this was an essential piece of equipment at any iron forge. It is likely that the Bridgnorth Foundry supplied castings to many ironworks; in 1800 it equipped a furnace at Aberdare in South Wales, partly owned by John Thompson who was also partner in a forge at Hampton Loade. Within a short period, Hazledine himself became a partner with Thompson, firstly at Hampton Loade forge and then the Stanley Colliery in Highley, which opened around 1803. Hazledine soon abandoned his interest in Stanley but quickly appears to have become the senior partner at Hampton Loade forge, whilst maintaining his share in Bridgnorth Foundry.

Bridgnorth Foundry was at its most productive in the early years of the 19th century. It was during this period that it came to the attention of Richard Trevithick and of course built Catch-me-who-can. It is clear that Hazledine was an imaginative engineer who at the very least could attract high calibre individuals to work for him at Bridgnorth. I very much doubt if Trevithick would have turned to Bridgnorth if it had not been for Hazledine’s management.

It seems as though Hazledine’s creditors had never properly been paid and after 1807 there appear to have been renewed problems with them. Nonetheless, he seems to have remained focused on his work; in 1810 he took out a patent for a new type of plough. Unfortunately his health was now poor and he died on the 28th October 1810. He was buried in St Mary’s churchyard, with a cast iron memorial cast at the foundry; he deserves to be better known.

Cleobury park furnace

The Four Parishes Heritage Group now have the final report on the geophysical survey carried out by Dr Tim Young and his colleagues at GeoArch on Cleobury Park blast furnace, deep in the Wyre Forest.

Before the survey began, we knew a little of the history of the furnace. It was one of a pair of blast furnaces built by Robert Dudley, Earl of Leicester around 1570. It took iron ore, from either the Wyre Forest or the Clee Hill and converted it into cast iron. This in turn was sent to forges at Cleobury to be refined into wrought iron for use by blacksmiths. Cleobury Mortimer and much of the Wyre Forest at that period belonged to the Crown; Dudley was a particular favourite of Queen Elizabeth I and she gave him her lands in Cleobury and the forest in 1563. At this date there was no furnace; however, by 1571 an iron forge was operating at Cleobury Mortimer and this in turn implies that a blast furnace was in operation. By 1576 there were two furnaces at work in the Wyre Forest, owned by Dudley but leased to John Weston, who lived at Cleobury Lodge, near Wall Town in Neen Savage. One of the furnaces was on the site of Furnace Mill, later converted to a corn mill and now a house. However, the existence of Cleobury Park furnace was largely overlooked by historians until it was rediscovered by the late David Chapman, an archaeological surveyor employed by the Ordnance Survey. David published an account of his work in the Cleobury Chronicles.

David established that there were three dams along Baveney/Dowles brook, between Cleobury Lodge and Furnace Mill. There was no evidence for any furnace at the first two of these, but at the third dam there was a mass of glassy slag. This is the waste product from a blast furnace. In the furnace, iron ore is heated with charcoal to produce molten iron, but the impurities in the ore react with limestone to give a slag. The iron is run off into moulds for casting or for conversion to wrought iron, but the slag has no use beyond a fill for roads and so would be left behind. There can be no doubt that the lower dam was the site of the second, previously lost, blast furnace.

The dam itself is about 15 feet high and runs for about 45 yards across the valley of the Dowles. At its south end it is breached by the Dowles but there is another gap at the north end, around 15 feet across. This leads into a long, wet hollow that leads back to the brook; to the one side, just below the dam, is a pronounced hollow, surrounded by slag. An early blast furnace has two essential components. It has a waterwheel, to power a set of bellows which provide the blast of air into the furnace. Then there is the furnace itself, where a temperature of 1600º C can be reached, to produce molten iron. The gap at the north end of the dam looked like the space where a water wheel might have been situated, with the wet hollow being the remains of the channel that would return the water to the brook. The other hollow would be in a good place for a furnace. This appeared to be a compelling interpretation of the site. The work by Tim and GeoArch has also shown that it is totally wrong.

The widest known water wheel at any 16th or 17th century blast furnace is under 3 feet. This would not require a 15 foot channel as exists at the north end of the dam. The furnace itself would be expected to be about 5 yards square in plan; the geophysics showed nothing resembling that on the site. It now seems that the north channel was an overflow channel. One of the main functions of the dam was to store water for the lower furnace at Furnace Mill; there would have been a timber sluice gate that would be opened when iron making was being carried out at that site, to ensure there was enough water to power its bellows.

It is absolutely certain that there was a blast furnace at Cleobury Park, due to the vast quantity of slag there. However, this was at the south end of the dam. It seems that the water wheel was where the Dowles currently flows. When the site was eventually abandoned, this is where the dam was breached to allow a free flow of the brook. Careful inspection of the banks of the brook show not only that most of the slag is actually on the south side, there is also a lot of stone and brick in the bank as well. This may well be one side of the wheelpit. The geophysics did not show any clear evidence for the furnace, but we now believe that this is because it has either been swept away by the brook, or perhaps more likely, it is to be found on the south bank.

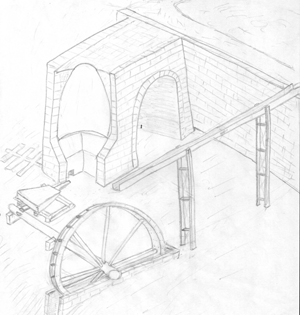

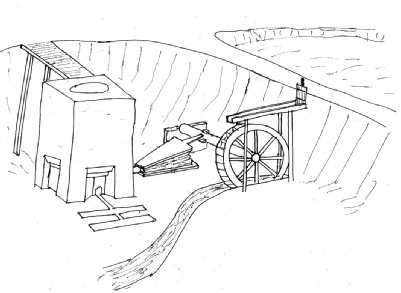

Figure 1. Sketch of the arrangement of waterwheel, bellows and furnace at Cleobury Park. A wooden platform from high ground south of the furnace would probably have allowed access to the top of the furnace, to load it with iron ore and charcoal. The casting area would have been on the opposite side of the furnace. This illustration is purely diagrammatic; the bellows and the casting areas would have been in roofed buildings, built against the furnace.

Figure 1. Sketch of the arrangement of waterwheel, bellows and furnace at Cleobury Park. A wooden platform from high ground south of the furnace would probably have allowed access to the top of the furnace, to load it with iron ore and charcoal. The casting area would have been on the opposite side of the furnace. This illustration is purely diagrammatic; the bellows and the casting areas would have been in roofed buildings, built against the furnace.

Looking at slag

Most people will know that for the last five years, the Four Parishes Heritage Group have been carrying out an archaeological study of the local iron industry. As part of this we have excavated two medieval iron furnaces in Chorley and Billingsley (one around 1200, the other from 1450), identified the site of another on the Clee Hill and also carried out a geophysical survey of a Tudor blast furnace in the Wyre Forest, Cleobury Park blast furnace.

In addition to carrying out work on the sites of our furnaces, we also have collected samples of materials from them. An iron furnace takes in iron ore and charcoal and produces iron and slag, the waste product from the ore. The iron itself is usually in short supply at any furnace, as it would of course have been taken away to be sold. Last month I wrote about some of findings about the charcoal. This month I want to describe what we have found out from studying the iron ore and the slag.

Before considering our findings, it is worth briefly considering the different types of processes used to make iron. Our medieval furnaces were bloomeries; in these the temperature was hot enough to cause the impurities to melt, so they could be run off as a liquid slag, but the iron itself remained as a spongy mass in the bottom of the furnace. However, in Tudor times the blast furnace was introduced. This used much bigger bellows to get the temperature hot enough to melt both the impurities and the iron. The impurities would form a layer on top of the liquid iron; they would first be tapped off, then the iron would be run off into moulds, to make castings.

The slag analysis from our bloomeries shows that they were extracting around half the iron from the iron ore; the rest ended up in the slag. This meant that for every pound of iron ore used in the furnace, they would get ½ a pound of iron and 2 pounds of slag. This was actually good for a bloomery. It is likely that the iron produced would be very hard, resembling steel in its qualities. The ores used by the two bloomeries seem slightly different; possibly the way they were prepared for the furnaces changing over time. The slags themselves are pretty similar between both bloomeries, even though the furnaces were 250 years apart. The slags resemble those found at a number of other late medieval sites, where some archaeologists have argued that their composition suggests that the furnaces were being run as hot as possible to try and produce molten iron. The fact that we find this type of slag in a much earlier furnace suggests that this is not the case and the composition of the slag simply reflects the type of ore being used.

When we looked at the slag from Cleobury Park blast furnace, we had a very specific question in mind. By the 17th century, limestone was routinely being added to blast furnaces as a flux. This helped the impurities to melt and settle out from the liquid iron. However, it is not known when this was first introduced. The slags from Cleobury Park, dating from the 16th century, show small traces of lime. From this we conclude that limestone was being added to the iron ore and charcoal, but only in relatively small amounts; about 10% by weight of the total charge. In later furnaces this was increased to around 30%. The slag does not seem to have flowed very freely, even when molten. On the other hand, almost all the iron was successfully extracted, unlike in the bloomeries. The iron ore appears very similar to that used at our two bloomeries; we suspect that it might have been mined from much the same area: Billingsley, Chorley and Baveney Wood.

Our next step is to try and look at the slag and iron ore from the Clee Hill.

The Four Parishes Heritage Group would like to thank the Cleobury and Rural Local Joint Area Committee for financial support for their work.

Dating the iron industry

Most people will be aware that for the last five years the Four Parishes Heritage Group have been investigating two old ironworks (or ‘bloomeries’ as they were called) in Chorley. We carried out excavation at these in 2009. One site, between Billingsley and Chorley, gave us a lot of pottery which we could confidently date to around 1200- 1300. However our second site, between Rays Farm and Chorley village, gave only a very few pieces. One of these looked to be from a ‘skillet’, a type of frying pan that was used in the 15th century. We also had a documentary reference to a ‘bloomsmithy’ at work somewhere in Stottesdon in 1455. In this document, the lord of the manor of Stottesdon sent his steward first to the Forest of Dean and then to Sheffield to try and find a man who could operate his bloomery. We decided that the most likely scenario was that this was our bloomery and that it was new in 1455. As it was not mentioned in a set of accounts for Stottesdon for 20 years later, our assumption was that it probably had worked for only a relatively short time.

It is always dangerous to make too many assumptions… Whilst the site gave us very little pottery, we did have an abundance of charcoal. This was the fuel which was used to heat the furnace and make the iron. Charcoal is made from wood and is a form of carbon. As any follower of TV archaeology will know, wood can be dated by radiocarbon dating. The technique relies on the fact that plants, including trees, take in carbon dioxide from the air and this becomes incorporated into their structures. A small proportion of carbon dioxide is naturally radioactive, and so the plant is also slightly radioactive whilst it is alive. Once it dies, it stops absorbing the radioactive carbon dioxide. Over a period of several thousand years, this radioactivity will decay and finally vanish. Thus the smaller the proportion of radioactivity in a sample, the older it is.

We decided to send some of the charcoal to a laboratory in the United States for carbon dating; surprisingly this was quicker and cheaper than sending the sample to any lab in the UK! We got our results just before Christmas; there was an 85% chance that our charcoal had been made between 1400 and 1440. There was a 10% chance it might have been a little earlier but there was only a 5% chance that it could have been later. So we were almost certainly wrong in assuming that our bloomery started work in 1455; it must have been significantly earlier than that.

Coupled with the radiocarbon date, we also had a more detailed analysis of the few pieces of pottery that we recovered from the site. Whilst there was not much of this, it covered a much wider date then we thought. The earliest looked as though it was from the 1300s; it would just be possible to push this into the 1400s, if it was assumed that the vessel was old when it was broken and thrown away. Our 15th century skillet now was much more likely to be 16th! Putting this with our radiocarbon dating, it looks as though our site started work some time in the early 1400s; say about 1420 and carried on working for roughly 100 years.

So where does this leave our document? We now think that the search for the new operator was not because the works had been newly established. Rather the works were already present, but either the previous operator had left or had died. Rereading the accounts, we can also see that a carpenter, John Grove, was paid for making a new dam for the bloomsmithy, but he was not paid for anything else. We think this was because the furnace building, the waterwheel and the bellows were already there, but the previous dam was past its best and needed replacing. Indeed, this may be connected with the need to find a new operator! So rather than being a brief and unsuccessful experiment, this second bloomery in Chorley (which we also now know was called ‘Cindermill’) had a life equivalent to the earlier one.

We would like to thank the Cleobury and Rural Local Joint Committee and the Shropshire Archaeological Society for helping to fund our radiocarbon dating.